From Robots to Systems:

How Shandong Chenxuan Is Aligning with the Next Wave of Intelligent Automation

Jinan / Tokyo —

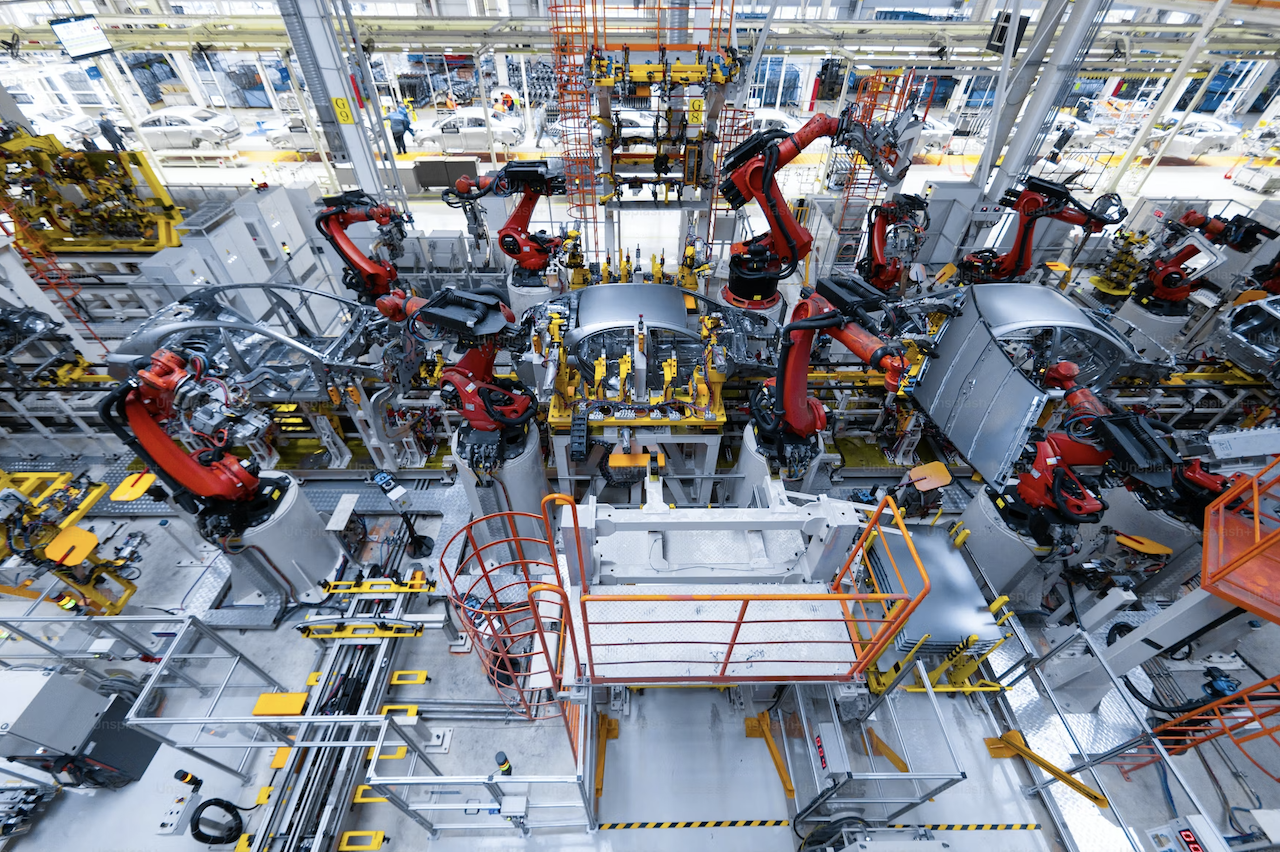

As Japan’s major industrial exhibitions continue to showcase the future of manufacturing, one message is becoming increasingly clear: the competitive frontier of automation is shifting away from standalone robot hardware toward system-level intelligence, driven by end effectors, machine vision, AI-assisted process planning, and software-defined integration.

For global manufacturers and system integrators alike, this shift marks a structural change. Automation is no longer evaluated solely by robot payloads or axis counts, but by how effectively perception, process logic, and execution are integrated into a scalable production system.

Against this backdrop, Shandong Chenxuan Robot Technology Co., Ltd., a China-based automation integrator and solution provider, is repositioning itself to address the next phase of intelligent manufacturing—particularly for overseas and cross-border industrial projects.

Japan’s Automation Exhibitions as a Leading Indicator

Japan has long served as a bellwether for industrial automation trends, and recent exhibitions across robotics, factory automation, and advanced manufacturing have reinforced several emerging priorities.

End Effectors Take Center Stage

Once considered auxiliary components, end effectors are now a focal point of productivity improvement. From compliant grippers and quick-change tooling to welding torches, force-controlled polishing heads, and adaptive fixtures, tooling intelligence increasingly determines cycle time, quality stability, and production flexibility.

In many applications, the effectiveness of the end effector now outweighs the specifications of the robot arm itself.

Vision Becomes Production Infrastructure

2D and 3D vision systems—used for positioning, seam detection, inspection, and traceability—are rapidly transitioning from optional upgrades to foundational infrastructure. The emphasis has shifted from “seeing” to directly driving motion and process decisions.

This integration reduces reliance on manual alignment and expands the feasibility of flexible automation in real-world factory conditions.

AI Moves into the Process Loop

While AI has been widely demonstrated in recognition tasks, its industrial value is increasingly measured by its ability to close the loop between perception and execution. AI-assisted path generation, adaptive parameter tuning, and real-time compensation are beginning to replace static, pre-defined logic.

The emerging focus is not AI as a showcase feature, but AI as a practical process enabler.

Offline Programming and Digital Twins Gain Strategic Importance

Offline programming (OLP), simulation, collision detection, and cycle-time validation are no longer confined to large OEMs. They are becoming essential tools for reducing commissioning time, minimizing downtime, and ensuring predictable project delivery—particularly in overseas deployments.

Chenxuan’s Approach: Turning Integration into a Scalable Capability

Shandong Chenxuan’s strategy reflects a broader industry realization: integration experience itself must become productized.

Standardized Automation Cells

Rather than treating each project as a fully bespoke effort, Chenxuan is advancing modular automation cells for high-frequency scenarios, including robotic welding, material handling, surface processing, and inspection. These cells combine robot platforms with predefined tooling interfaces, vision logic, safety architecture, and process templates.

The result is faster deployment, reduced engineering uncertainty, and greater consistency across projects.

Data-Driven Process Engineering

Beyond mechanical integration, Chenxuan is emphasizing the structuring of process knowledge. Welding parameters, motion strategies, vision feedback, and quality criteria are being organized into reusable frameworks rather than isolated project files.

This approach enables incremental improvement over time, allowing systems to benefit from accumulated engineering data rather than restarting from zero with each new deployment.

Software-Defined Delivery

In international automation projects, delivery speed and predictability often matter as much as capital cost. By strengthening CAD-driven planning, offline simulation, and parameterized programming architectures, Chenxuan aims to reduce on-site commissioning cycles while maintaining reliability.

In this model, delivery capability itself becomes a competitive differentiator.

Why Japan’s Model Matters for Global Integrators

Deep component specialization, disciplined interface standards, and rigorous attention to engineering detail characterize Japan’s automation ecosystem. For system integrators serving global markets, these characteristics provide a blueprint for scaling automation solutions beyond one-off projects.

Rather than replicating technology, Chenxuan’s approach emphasizes absorbing methodology—combining structured engineering practices with execution speed to meet the demands of international manufacturing clients.

Looking Ahead: Automation as a Learning System

As robot hardware becomes increasingly standardized worldwide, differentiation will depend on higher-level capabilities:

- The ability to adapt systems across product variants

- The integration of vision and AI into executable process logic

- Predictable, accelerated delivery cycles

- The accumulation and reuse of process knowledge over time

Shandong Chenxuan Robot Technology’s current trajectory reflects this shift. The next phase of industrial automation will not be defined by how many robots are deployed, but by how effectively systems learn, adapt, and scale.

For manufacturers navigating global supply chain restructuring and rising efficiency demands, this systems-level perspective is rapidly becoming essential.

Post time: Dec-18-2025