Due to the increasing labor costs and product update iteration speed in 3C electronics industry, all enterprises are looking for the best solution.

Due to the increasing labor costs and product update iteration speed in 3C electronics industry, all enterprises are looking for the best solution.

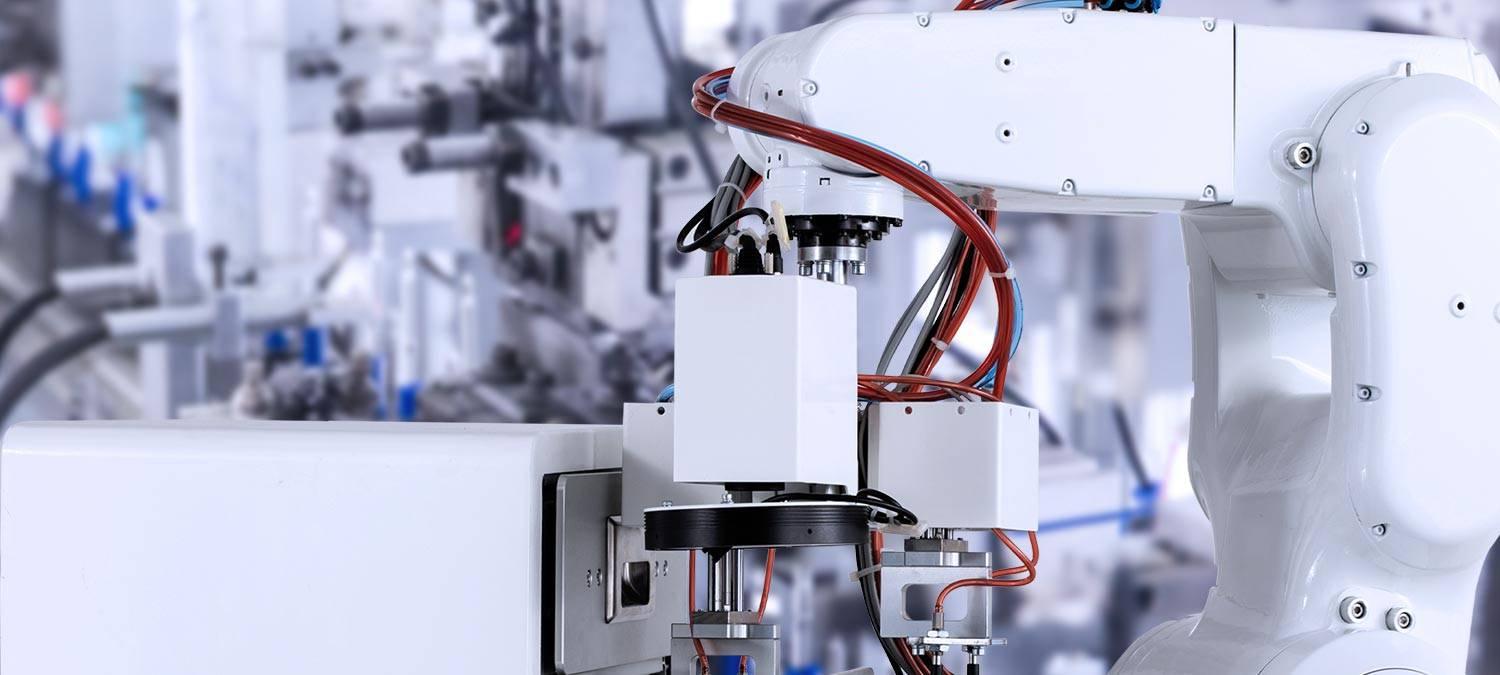

Project introductionIndustrial Advantages of Collaborative Robots

Higher speed

Online trajectory planning based on dynamics, with maximum synthesis speed reaching 7 m/s

High precision dynamic modeling and parameter identification, speed and inertia feedforward technology, giving full play to the limit performance of hardware

More accurate

High precision global error compensation, repeated positioning accuracy up to ±0.015 mm

The accurate and smooth path is more suitable for precise operation scenarios such as glue spreading

More reliable

Ensure long-term reliable operation of core components from the aspect of hardware and software design.

The product has passed IP67, CE, CR and other certifications, 0°C~45°C operation test and 120 hours of delivery test.

More space saving

Collaborative Small Load Robot with Minimum Space Occupancy

The elbow form is provided for the tail outgoing line at the main body end is provided with to reduce the space occupied by the outgoing line.

The robot cable and motor are built-in, and the user can easily wire through the arm interface.

More Easy to Use

Support remote control function and secondary development interface SDK

Support CC-Link, Modbus (TCP, RTU), PROFINET, Ethernet/IP, EtherCAT and other bus protocols

Support serial port, TCP/IP and other communication modes

Simple maintenance, timely, professional and efficient service