FANUC ARC Welding Robot Arm Automated MIG TIG Welding for Industrial Production

Product Description:

Shandong Chenxuan Robot Technology Co., Ltd. offers FANUC ARC welding robot systems with custom fixtures and integration. High-speed MIG/TIG automation ensures quality welds, stable performance, and long-term reliability for factory production lines.

Parameter:

|

Specification |

Value |

| Axes | 6 controlled axes |

| Maximum payload (wrist) | Up to 25 kg for ARC Mate 120 i D. For 100iC / 100iD models: 12 kg |

| Reach | ~1441 mm for 100iD; ~1831 mm for 120iD |

| Repeatability | ± 0.02 mm typical for models like 100iD |

| Mounting options | Floor, upside-down (ceiling), angle mount |

| Wrist/arm features | Hollow wrist for integrated torch/hose routing; improves access in narrow spaces. |

| Protection / environment | For some models: wrist standard IP67 for harsh environments. Example: ARC Mate 50iD has IP67 for wrist. |

| Controller | Compatible with FANUC controllers such as “R-30 i B” (100iD) and earlier series. |

| Application focus | Designed for arc welding (MIG/TIG), narrow jig spaces, integrated hose-pack, material removal also possible. |

Function:

Applications of FANUC ARC Welding Robot Series

1. Metal Fabrication & Structural Components

Used for welding steel frames, machine parts, beams, and custom fabrication structures. Ensures consistent welding quality, smooth seams, and minimal spatter for industrial-grade production.

2. Automotive & Transportation Industry

Ideal for car body panels, seat frames, mufflers, and chassis welding. The high-speed FANUC ARC robots deliver precise, repeatable welds for automotive manufacturing and OEM suppliers.

3. Pipe & Pressure Vessel Welding

Integrated systems for welding cylindrical or conical workpieces such as tanks, tubes, and drums. The hollow wrist design allows clean torch routing, ensuring access to tight joint angles.

4. Agricultural & Construction Machinery

Applied in large-scale equipment manufacturing — loaders, excavators, tractors, and frames — where strong, continuous welds are essential for safety and durability.

5. Sheet Metal & Furniture Production

Automates the welding of small- to medium-sized sheet-metal parts, brackets, and frames. Greatly reduces manual labor while maintaining uniform bead quality in high-volume operations.

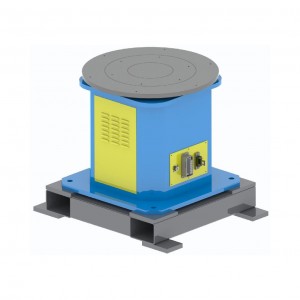

6. Tooling, Jig & Fixture Manufacturing

Enables precision welding for fixture bases, jigs, and modular tooling systems, improving assembly accuracy and repeatability in production lines.

7. OEM and Turnkey Integration Projects

When integrated by Shandong Chen Xuan Robot Technology Co., Ltd., the FANUC ARC series becomes a complete solution — including fixture design, safety guarding, offline programming, and robot-to-welder communication for fully automated welding cells.

video:

Our robot

packaging and transportation

exhibition

certificate

Company History