Single Axis Positioner/Automatic Welding Positioner

Technical Parameters

|

Single-axis horizontal servo positioner |

Single-axis main trunk type servo positioner |

Spindle box type single-axis servo positioner |

|||||||||

|

Serial number |

PROJECTS |

Parameter |

Parameter |

REMARKS |

Parameter |

Parameter |

Parameter |

REMARKS |

Parameter |

Parameter |

REMARKS |

|

1. |

Rated load |

200kg |

500kg |

Within R300mm/ R400mm radius of main axis |

500kg |

800kg |

1200kg |

Within R400mm/R500mm/ R750mm radius of main axis |

200kg |

500kg |

It is within R300mm radius of spindle axis Internal, distance of center of gravity to flange ≤300mm |

|

2. |

Standard radius of gyration |

R300mm |

R400mm |

R600mm |

R700mm |

R900mm |

R600mm |

R600mm |

|||

|

3. |

Maximum rotating angle |

±360° |

±360° |

±360° |

±360° |

±360° |

±360° |

±360° |

|||

|

4. |

Rated rotating speed |

70°/S |

70°/S |

70°/S |

70°/S |

50°/S |

70°/S |

70°/S |

|||

|

5 |

Repeat positioning accuracy |

±0.08mm |

±0.10mm |

±0.10mm |

±0.12mm |

±0.15mm |

±0.08mm |

±0.10mm |

|||

|

6 |

Size of horizontal rotary disc |

Φ600 |

Φ800 |

- |

- |

- |

- |

- |

|||

|

7 |

Boundary dimension of displacement frame (length×width×height) |

- |

- |

2200mm ×800mm ×90mm |

3200mm ×1000mm ×110mm |

4200mm ×1200mm ×110mm |

- |

- |

|||

|

8 |

Overall dimension of position shifter (length×width×height) |

770mm ×600mm ×800mm |

900mm ×700mm ×800mm |

2900mm ×650mm ×1100mm |

4200mm ×850mm ×1350mm |

5400mm ×1000mm ×1500mm |

1050mm ×620mm ×1050mm |

1200mm ×750mm ×1200mm |

|||

|

9 |

Spindle rotary disk |

- |

- |

Φ360mm |

Φ400mm |

Φ450mm |

Φ360mm |

Φ400mm |

|||

|

10 |

Center height of the first axis rotation |

800mm |

800mm |

850mm |

950mm |

1100mm |

850mm |

900mm |

|||

|

11 |

Power supply conditions |

Three-phase 200V±10%50HZ |

Three-phase 200V±10%50HZ |

With isolation transformer |

Three-phase 200V±10%50HZ |

Three-phase 200V±10%50HZ |

Three-phase 200V±10%50HZ |

With isolation transformer |

Three-phase 200V±10%50HZ |

Three-phase 200V±10%50HZ |

With isolation transformer |

|

12 |

Insulation class |

H |

H |

H |

H |

H |

H |

H |

|||

|

13 |

Net weight of equipment |

About 200kg |

About 400kg |

About 500kg |

About 1000kg |

About 1600kg |

About 200kg |

About 300kg |

|||

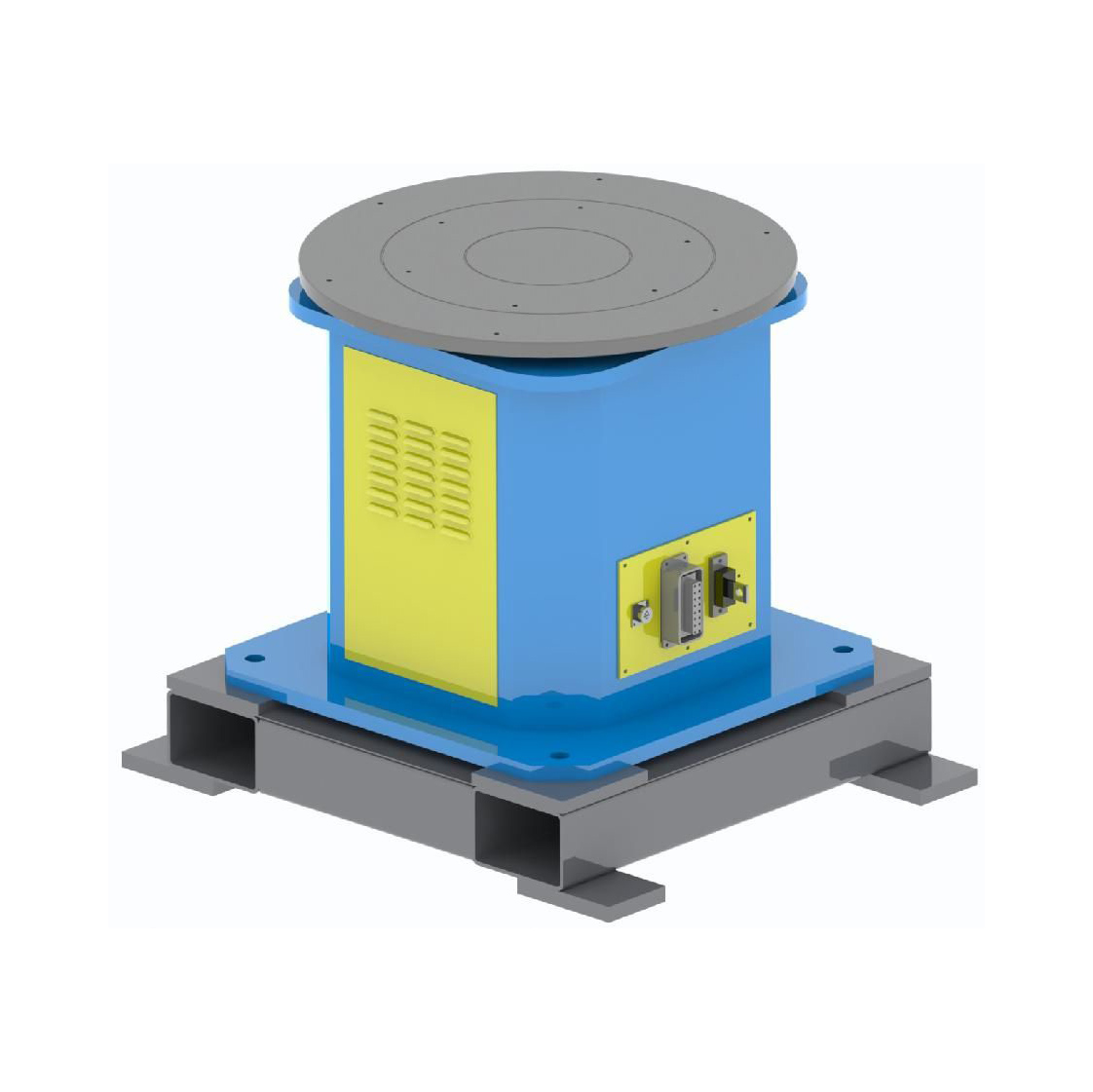

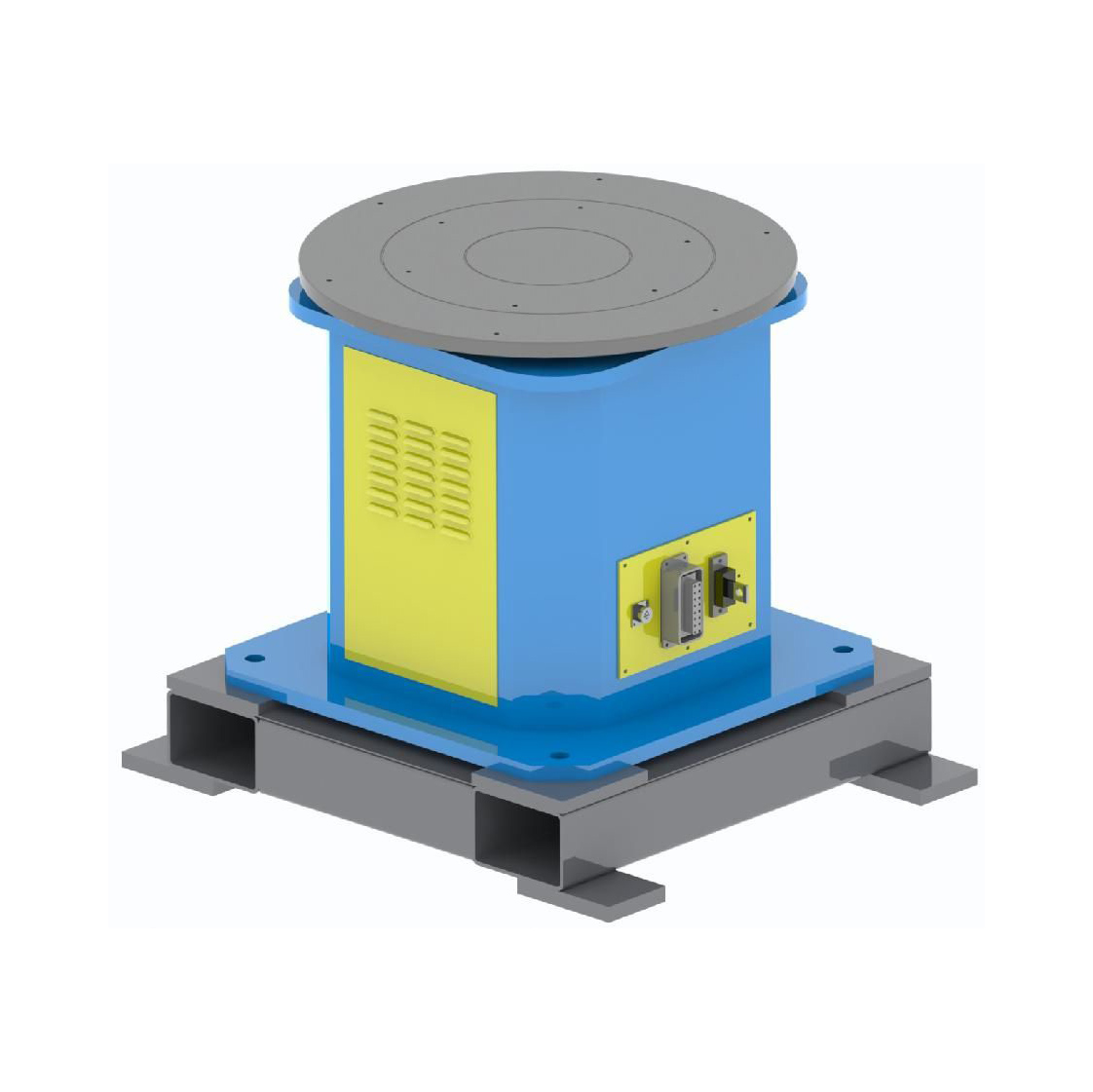

Single-axis horizontal servo positioner

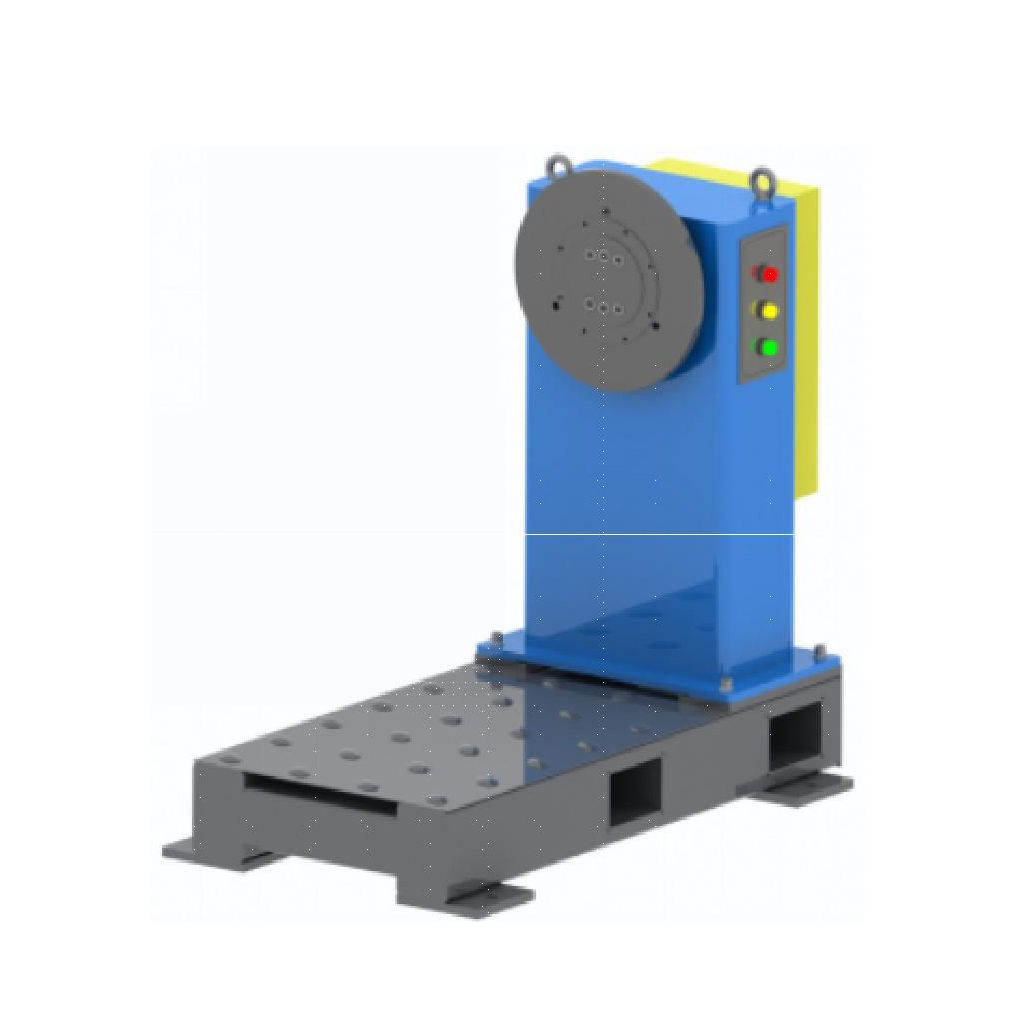

Single-axis main trunk type servo positioner

Spindle box type single-axis servo positioner

Structure Introduction

The single-axis horizontal servo positioner is mainly composed of integral fixed base, rotary spindle box, horizontal rotary disk, AC servo motor and RV precision reducer, conductive mechanism, protective shield and electric control system. The fixed base is welded with high-quality profiles. After annealing and stress relieving, it shall be processed by professional machining to ensure high machining accuracy and use precision of key positions. The surface is sprayed with anti-rust appearance paint, which is beautiful and generous, and the color can be customized according to customer requirements.

The high-quality profile steel selected for the rotary spindle box can ensure its long-term durability and stability after welding and annealing and professional machining. The horizontal rotary disk is welded with high-quality profiles. After annealing treatment, professional machining can ensure the degree of finish of the surface and its own stability. The upper surface is machined with screw holes with standard spacing, which is convenient for customers to install and fix the positioning tooling.

Selecting AC servo motor and RV reducer as power mechanism can ensure the stability of rotation, accuracy of positioning, long durability and low failure rate. The conductive mechanism is made of brass, which has a good conductive effect. The conductive base adopts integral insulation, which can effectively protect servo motor, robot and welding power source.

The electric control system adopts Japanese Omron PLC to control the positioner, with stable performance and low failure rate. The electrical components are selected from famous brands at home and abroad to ensure the quality and stability of use.