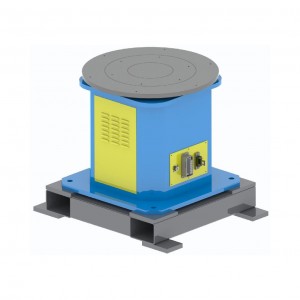

Lift platform

Function:

Don’t Let “Short Arms” Hold Back Your Production Line: The Collaborative Robot Lift Table

The “Invisible 7th Axis” for Palletizing Efficiency When your collaborative robot is still repeatedly adjusting its path just to “reach high pallets,” and when your warehouse has empty space but you’re forced to rent more because of limited stacking height – what you need isn’t a more expensive long-arm robot, but an “efficiency booster” for your existing equipment: the collaborative robot lift table.

It’s the “Invisible Leg” That Lets Robots “Grow Taller” Most standard collaborative robots have an operating height of around 800mm, barely able to stack 2-3 layers of boxes. This leaves the upper warehouse space effectively “wasted.” But when paired with this lift table, the operating height can be extended directly to over 1400mm, jumping from 2 stacking layers to 5-6 layers. It’s like turning your previously “underutilized” horizontal warehouse space into vertical, usable area – boosting space utilization by over 40%.

More importantly, it’s not just a “standalone device”; it’s an “extension of the robot’s 7th axis.” Whether you use FANUC, UR, or other mainstream brands, the built-in dedicated plugins enable “plug-and-play” functionality. No need to modify programs or dismantle the production line – installation takes just 1 hour, and your robot can “unlock new capabilities” the same day. ## It’s the “Stabilizer” for “Stable, Fast, and Accurate” Palletizing Many factories worry about “shaky lifting equipment,” but this lift table features a high-rigidity column and low-deflection design, pushing the dynamic bending moment to 1400N·m. Even when the robot is moving at high speed with a 100kg heavy box, the lift table stays as stable as if it’s “welded to the ground.”

Palletizing accuracy is controlled within ±2mm, so boxes stack neater than if arranged manually – eliminating the hassle of rework caused by “tilted or fallen boxes.” Speed is another highlight: it maintains an operating speed of 100mm/s even under a 100kg load, and can “synchronize movements” with the robot. While other setups have the robot moving “while the lift table waits,” your production line will have the robot “grabbing boxes + the lift table rising” simultaneously 、speeding up palletizing cycles by 30%and ensuring no delays during peak seasons. It’s a Cost-Effective Champion for “Big Results at Low Cost” Replacing a collaborative robot with a long-arm version costs at least twice as much as your current equipment. But adding this lift table requires only 1/3 the cost of a long-arm robot while delivering nearly the same high-palletizing performance. What’s more, it’s versatile across scenarios: whether handling food boxes, electronic component cases, or chemical packaging, and from 5kg light boxes to 100kg heavy boxes, it can “hold and transfer stably.” Even if you upgrade to a new robot later, it can still be used with compatible plugins – meaning one investment covers “height upgrades” for multiple generations of equipment. For factories, “saving space saving rent, boosting efficiency saving labor costs, and low investment fast ROI.” This lift table packages all three “savings” into your production line: install it today, and your robot will stack higher, your warehouse will store more, and your production line will run faster – with ROI achievable in as little as 3 months. Don’t let your robot’s “short arms” become a bottleneck for production line upgrades – add a lift table, let your equipment “stretch its legs,” and maximize both warehouse space and efficiency.

Our robot

packaging and transportation

exhibition

certificate

Company History