Versatile and Efficient Robot Cantilever Welding Workstations for Automotive, Aerospace, and Heavy Industries

Main Features:

1. Adaptable to multiple welding methods:

Whether it is spot welding, seam welding, laser welding, or TIG and MIG welding, this workstation can be flexibly configured to suit various welding process requirements and meet different production needs.

2. Space-saving and high accessibility:

The cantilever structure allows the robot to cover multiple workstations while saving a significant amount of floor space. It is especially suitable for applications with limited space or requiring high accessibility, such as welding complex-shaped workpieces or processing irregular parts.

3. Intelligent control and monitoring:

The robot cantilever welding workstation is equipped with an intelligent control system that can monitor the welding process in real-time, automatically adjust welding parameters, and provide fault diagnosis and alerts, ensuring stable welding quality while greatly reducing the need for manual intervention.

4. Enhanced safety:

When the robot performs welding operations, operators maintain a safe distance from the welding process, reducing exposure to high temperatures, welding fumes, and other potential hazards, ensuring a safe production environment.

Video

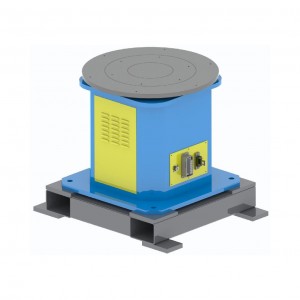

Product Display

Our robot

packaging and transportation

exhibition

certificate

Company History